What are these technologies and what do they do?

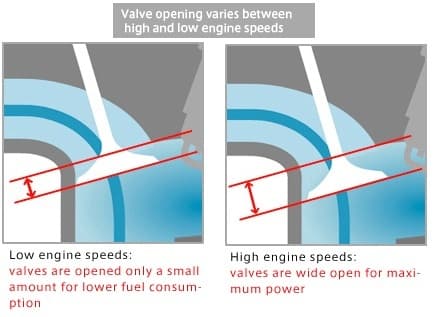

A normal engine (that does not use these technologies) breathes by opening / closing of intake and exhaust valves. The amount of lift that these valves have, the time at which they open and the duration of the lift during the combustion cycle are fixed in case of an engine that does not use the technology like VTVT, VVT etc.This is a compromise since the valve opening requirements for an engine while it is breathing at low RPM is not the same as when the engine is running at a higher RPM. These technologies effectively manage the valve timing and lift during the combustion cycle based on engine rpm.

What do the Acronyms VTVT / VVT / i-VTEC / VVT-i / Ti-VCT etc. mean?

VTVT – Variable Timing Valve TrainVVT – Variable Valve Timing

VVT-i – Variable Valve Timing with Intelligence

i-VTEC – Intelligent Variable Valve Timing and Lift with Electronic Control System

Ti-VCT - Twin Independent Variable Camshaft Timing

Are there any differences between these technologies?

How do these technologies affect the car’s performance?

Variable valve timing and lift make the engine more responsive to throttle inputs and all such engines generally have better low end power in comparison to the engines that do not use this technology. Another great benefit is the improved fuel efficiency and reduced emissions. (If you see the video above, you would notice how the valve lift changes with engine speed. The images present below show the variation that happens over different speeds.) The variation may look small, but in effect multiplied with engine speed has great impact over engine performance parameters.Which manufacturers use these technologies?

Almost all manufacturers use these technologies in their advanced range of powerful engine. In fact it has become more or less a norm to use these, because without them, it would be impossible to meet the strict emission norms that are in place.VTVT – Hyundai

VVT & VVTi – Toyota, Maruti Suzuki

i-VTEC – Honda

Ti-VCT - Ford

Are there any other lesser known derivatives of these technologies?

The VVT evolved into what is now known as VVT-i, similarly there are other technologies like VVTL-i which also creates variable lift, Dual VVT-i, Valvematic, Valvetronic, VVEL, VANOS etc. All these are technologies that aim to create variable valve timing or modify timing along with modifying the amount of lift.