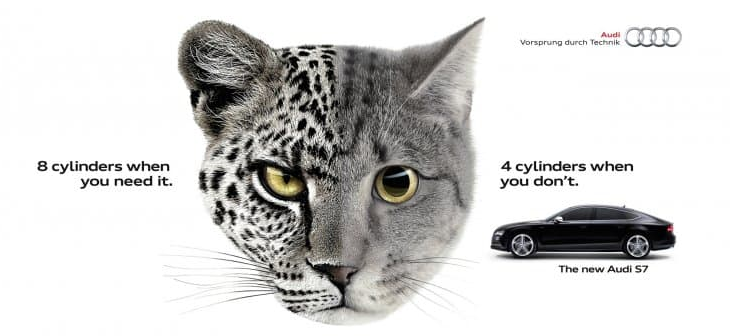

What does Cylinder Deactivation do?

A Cylinder Deactivation system downsizes the engine by shutting few of the cylinders of an engine, so that only the remaining cylinders burn the fuel.The pistons of the cylinders that are not burning the fuel still reciprocate without burning any fuel.

How does it exactly work?

A car does not require engine’s full capacity at all times and at times when you are using only part throttle at light loads, like for cruising, the engine can shut half of the cylinders and make it more fuel-efficient. An engine management system constantly monitors the engine speed, speed of the car, torque, gear, throttle position etc. based on these parameters it decides when to deactivate the cylinders.

It’s job is not only to shut the cylinders and put them back to work when there’s a need, it’s job is to do so in the most imperceptible and unnoticeable manner to the driver. For this reason, the engine management ensures that at the time when some of the cylinders are shut, the throttle opening for rest is increased simultaneously, so that the remaining cylinders can maintain the required torque that all cylinders were collectively producing. Also, the ignition timing is adjusted for the active cylinders to accommodate the changed throttle input.

It’s job is not only to shut the cylinders and put them back to work when there’s a need, it’s job is to do so in the most imperceptible and unnoticeable manner to the driver. For this reason, the engine management ensures that at the time when some of the cylinders are shut, the throttle opening for rest is increased simultaneously, so that the remaining cylinders can maintain the required torque that all cylinders were collectively producing. Also, the ignition timing is adjusted for the active cylinders to accommodate the changed throttle input.

The cylinders are deactivated by ensuring that the exhaust gases produced during the previous combustion stroke do not leave and the cylinder then acts as an air spring.

The cylinders are deactivated by ensuring that the exhaust gases produced during the previous combustion stroke do not leave and the cylinder then acts as an air spring.

How does it benefit?

The first direct benefit is the fuel efficiency jump which can be anywhere in the range of 7-20% depending upon the speeds and extent to which it’s engaged. Another great benefit is the marginally lower emissions that engine produces.Which manufacturers use this technology?

Many manufacturers have tried to utilize this technology under various names. Volkswagen calls it Active Cylinder Technology (ACT), Mitsubishi calls it Modulated Displacement, Honda’s system is known as Variable Cylinder Management.Does it impact performance?

As far as acceleration performance is concerned, cylinder deactivation does not impact performance in a detrimental way since switching OFF / ON the cylinders takes only a few milliseconds and all of this happens in a way that’s very unnoticeable. However, it does improve the fuel efficiency to a great extent if you drive in a relaxed manner.Is there a lesser known derivative of this technology?

No. However, most manufacturers have attempted cylinder deactivation only with larger engines that have more than four cylinders, because they are easier to balance and deactivation does not need to disturb the firing order in any way. Ford has been unique in that sense and has been doing experiments with a three-cylinder Eco-Boost engine that has won many awards already.

With a three cylinder engine, deactivating one of the cylinder can disturb the firing order and causes severe vibrations. For this reason Ford is trying out rolling cylinder deactivation. See the figure on the right which shows how the cylinders are dynamically deactivated based on the firing order.